Different NC tools have different characteristics and use direction

Milling cutter is a kind of rotary cutter with one or more teeth for milling. Each tooth of the cutter is equivalent to a turning tool, which is fixed on the rotary surface of the saw blade milling cutter. When milling, the cutting edge is longer, and there is no idle stroke, VC is also high, so the productivity is high. There are many kinds of milling cutters, which have different structures and are widely used. According to their uses, they can be divided into three categories: plane milling cutters, groove milling cutters and forming surface milling cutters. Milling cutters with general specifications have been standardized and are generally produced by CNC tool factories. This paper introduces the characteristics of several commonly used milling cutters and their specific application directions

Cylindrical milling cutters are generally made of high-speed steel. The spiral cutting edge is distributed on the surface of the cylinder without auxiliary cutting edge. The helical cutter teeth gradually cut and separate from the workpiece when cutting, so the cutting process is relatively stable. It is mainly used for machining narrow and long plane with width less than milling cutter length on horizontal milling machine.

According to the different processing requirements, cylindrical milling cutter can be divided into coarse tooth and fine tooth. The chip holding groove of coarse tooth is large, which is used for rough machining, and fine tooth is used for finish machining. When the outer diameter of the milling cutter is large, it is often made into inlaid teeth.

The main cutting edge is distributed on the surface of cylinder or cone, the end cutting edge is the auxiliary cutting edge, and the axis of the milling cutter is straight to the surface to be machined. According to the cutter tooth material, it can be divided into two categories: high speed steel and cemented carbide.

Compared with high speed steel milling cutter, cemented carbide face milling cutter has higher milling speed, better surface quality, and can process workpiece with hard skin and hardened layer, so it is widely used. Cemented carbide face milling cutter can be divided into three types according to the different device modes of blade and cutter tooth, i.e. all type, machine clamp welding type and indexable type.

Face milling cutter is mainly used in vertical milling machine or horizontal milling machine to process step surface and plane, especially suitable for processing large plane. The face milling cutter with main deflection angle of 90 ° can mill the step surface with wider bottom. When machining a plane with a face milling cutter, there are more cutter teeth involved in cutting together, and the polishing effect of the auxiliary cutting edge makes the surface roughness of the machined surface small. Therefore, it can use larger cutting parameters, higher productivity and wide use.

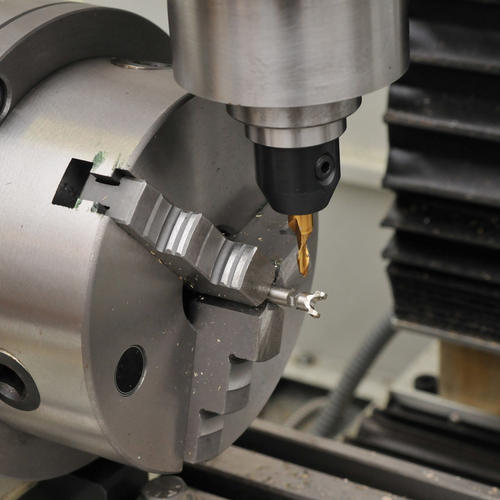

The end mill is a kind of milling cutter commonly used in NC milling. Its structure is that the cutting edge on the cylindrical surface is the main cutting edge, the end face is distributed with auxiliary cutting edge, and the main cutting edge is generally spiral teeth, which can add cutting stability and improve the machining accuracy. Because there is no cutting edge at the center of the end face of a general end mill, the end mill can not make axial feed when it works. The end face edge is mainly used to process the bottom plane which is straight with the side.

In order to improve the chip bending, increase the chip holding space and avoid chip blockage, the number of cutter teeth is relatively small, and the radius of chip holding groove arc is larger. Generally, the number of teeth of rough tooth end mill is 3 ~ 4, that of fine tooth end mill is 5 ~ 8, that of sleeve structure is 10 ~ 20, and radius of chip groove arc is 2 ~ 5mm. When the diameter of end mill is large, the structure of unequal pitch can be made to enhance the anti vibration effect and make the cutting process stable.

End mills with smaller diameters are generally made with shank. The end mills of φ 2 ~ φ 71mm are straight shank; the end mills of φ 6 ~ φ 63mm are Morse push shank; the end mills of φ 25 ~ 80mm are 7:24 taper shank with screw hole, which is used to tighten the cutter. The end mill with large diameter of 40 ~ 160mm can be made into sleeve structure.

End mill is mainly used for machining groove, step surface and forming surface by profiling. In addition, there are coarse tooth large spiral angle end milling cutter, corn milling cutter, carbide wave edge end milling cutter, etc. they have large diameter, can select large feed rate, and have high productivity.

Three side milling cutter can be divided into straight tooth three side edge and staggered tooth three side edge. It is mainly used in horizontal milling machine to process step surface and shallow groove through one end or two ends. In addition to the main cutting edge on the circumference, there are also auxiliary cutting edges on both sides of the cutter, which improves the cutting conditions, increases the cutting power and reduces the surface roughness value. However, after regrinding, the width scale changes greatly, and the insert tooth three side edge milling cutter can solve this problem.

The saw blade milling cutter is as follows. The saw blade cutter itself is very thin and only has cutter teeth on the circumference, which is used to cut off the workpiece and narrow the groove. In order to avoid knife clamping, the thickness is thinned from the edge to the center, so that the two sides form a secondary deflection angle.

Keyway milling cutter. Its shape is similar to that of end mill, except that it has only two spiral cutter teeth on the circumference. The edge of the end face cutter extends to the center, which is like both end mill and drill bit. Therefore, when milling the keyway with two ends blocked, it can make a proper amount of axial feed. It is mainly used for processing round head closed keyway. When it is used for processing, it is necessary to make multiple straight feed and longitudinal feed to finish the keyway processing.

Source: Zhongshan CNC tool http://yaoclub.cn

-

10-12

What are the causes of chip accretion on NC tools?

The reason is that the chip bottom metal is embedded in the micro uneven peak valley on the front cutter surface due to the large down pressure in the part close to the cutting edge, forming a gap free metal to metal touch, which is called the bonding area. In the bonding zone, there will be a thin layer of metal data accumulated on the rake face at the bottom of the chip. The metal data of this part of the chip is severely deformed and strengthened at the appropriate cutting temperature. With t

-

10-12

What are the wear types of tungsten steel milling cutters?

Abrasive wear machining materials often have some very hard particles, these particles will form grooves on the surface of the tool, which is the grinding loss. All surfaces are worn, especially the rake face. In addition, although the wear of hemp occurs at various cutting speeds, the wear caused by other reasons is not obvious due to the low cutting temperature at low cutting speed, so it is mainly the abrasion of abrasive materials. The lower the tool hardness is, the more serious the grindin